|

|

|

|

|

|

|

|

|

Features/Benefits

Excellent self-priming ability

• No non-return valve required in the inlet

• Single unbalanced/balanced seals to EN 12756 (DIN 24960)

• Mechanical seal with dry-running protection through oil bath quench

• Ideal for handling contaminated liquids

• Easy maintenance – Back-Pull-Out principle

• Flanges 32 and 40 threaded connection

• Flange connection 50 and higher to ISO 7005 PN 16

• Flange connection to ISO 7005 PN 20 (ANSI B16.5 150 lbs) optional

• Greased for life roller bearings

• Magnetic drive optional

• Atex certification |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Features/Benefits

Centrifugal pumps have a large application field and among

Johnson Pump’s most important segments can be mentioned:

• Industry For all types of applications demanding standardised,

DIN-normed pumps

• Hygienic For Food, Pharmaceuticals and Biotechnology

• Water handling For irrigation, drainage and fresh water

• Chemical/petrochemical For transport of slightly contaminated

thin liquids

• Greenhouse For heating, distribution of artificial fertilisers,

irrigation and drainage

• Marine For bilge pumping, engine cooling and as ballast pumps |

|

|

|

|

|

| |

In-line circulating pump with dry,

electric motor

|

|

|

|

|

|

|

Features/Benefits

• Compact and modular design

• Mechanical seal as standard

• Back-Pull-Out construction for easy maintenance

• Single and double speed execution available

• Shaft does not come into contact with pumped liquid

• Radial, closed impeller

• Special designed low NPSH suction inlet casing

• Vertical and horizontal mounting |

|

|

|

|

|

|

|

|

|

|

|

|

|

Features/Benefits

• Compact, space saving construction

• Economic design

• Back-Pull-Out construction for easy maintenance

• High pump efficiency

• Suitable for a wide range of duties

• Self-venting pump casing (horizontal execution)

• Easy maintenance

• Low maintenance cost

• Suitable for vertical arrangement

• Standard mechanical shaft seal EN 12756 (DIN 24690) |

|

|

|

|

|

|

|

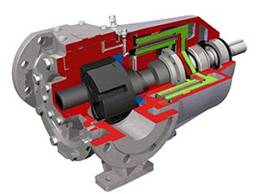

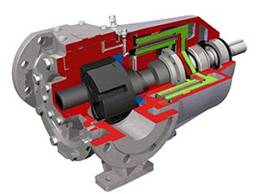

TopGear

TopGear H3

TopGear G

|

|

Gear pumps are used in all types of manufacturing

industries for the transportation of both thin and

thick liquids, from choccolate to diesel fuel.

Our gear pumps have sturdy design, offering high

reliability as well as long life

Features/Benefits

• Adjustable clearances Optimised efficiency

• Flange connection options (DIN, ANSI)

• Hard metal bearings and shafts available Long service life

• Front and back pull-out design Less maintenance downtime

• Big ports Low NPSHreq. Improved priming ability

Suitable for Pure or filled bitumen, pitch, diesel oil, crude oil,

lube oil, sodium silicate, acids, plastics, mixed chemicals,

isocyanates, paint, ink, resins, adhesives, acids, soap, lye,

kaolin, black liquor, lime, latex, sludge, chocolate,

cacao butter, fillers, sugar, vegetable fats and oils,

molasses and animal feed.

Technical data

General for G-series.

Casing: Cast iron

Idler and rotor: Nodular iron, Stainless steel

Max. differential pressure: 16 bar

Max. temp: 300?C |

|

|

|

|

|

| |

TopLobe - Tri-lobe Rotary Lobe Pump |

|

|

.

The TopLobe-series is available in 12 different sizes.

Shaft seal options include single and double mechanical

as well as lip seals. Multi-foot for vertical or

horizontal mounting. Heating/cooling systems

for front cover. Built-on safety relief valves

as an option. Connections from 20 mm to 150 mm

|

|

Features/Benefits

• Simple,clean and robust construction

Hygienic, minimum risk of product entrapment,

easy to clean either by CIP, SIP or manually,

short cleaning downtimes

• Easy maintenance

Easy service and maintenance,

simple gearbox construction

• Gentle product handling

Traditional tri-lobe design gives gentle handling,

low pulsation and capability of handling particles

• Large selection of shaft seals

Easily interchangeable with other seal types,

short downtimes

• Shim-free, oil lubricated gearbox

Easy to service, longer life |

|

|

|

|

|

| |

TopWing - Bi-Wing Rotary Lobe Pumps

|

|

|

The TopWing-series is available in 8 different sizes.

Shaft seal options include single mechanical, quenched,

double flushed, O-ring. Feet for vertical or horizontal mounting.

Safety relief valves are available built-on or separately.

Pre-heating/cooling devices in front cover and/or at the seals.

Connections from 25 mm to 100 mm.

|

|

Features/Benefits

• Superior hygiene

Self-draining rotorcase and mechanical seal assembled

in the liquid. Low carbon stainless steel with smooth

surfaces. Easy to clean – CIP, SIP or by hand, with

a minimum of entrapped liquid.

• Easy maintenance

Front-loaded product seals and robust bearing

assembly without shimming.

• Gentle product handling

Bi-Wing rotors with small clearances give a smooth

flow with little backslip. Able to handle particles.

• Large selection of shaft seals

Easily interchangeable with other

seal types, short downtimes

maximum 5 to 10 minutes.

• Integrated shaft and gear design

The complete pump is made in stainless steal.

The shaft bearings are integrated into the rotorcase.

Large shaft diameters and strong bearing design

results in small shaft defections and allows to have

small clearances inside hydraulic part.

The use of duplex steel for the rotors increases

wear resistance and improve behaviour on higher

temperatures. |

|

|

|

|

|

|

|

Closed coupled magnetic drive horizontal centrifugal pump to

ISO 5199 and ISO 2858 /EN 22858

|

|

Features/Benefits

• 100% leakfree

• Long life cycle, reduced maintenance costs

• Flanges according to ISO 7005 PN 16

• For stainless steel execution ISO 7005 PN20 /

150 lbs ANSI B 16.5 available

• Outstanding hydraulic performance

• High efficiency impeller

• Closed impeller with back vanes providing axial balancing

of impeller loads

• Half open impeller with wear plate

• Easy maintenance through the Back-Pull-Out principle

• Atex certification

• Outer rotor with safety bearing

• Somarium Cobalt high performance magnets

• Containment can in Hastelloy? for limited eddy current losses

• Silicon carbide pump liquid lubricated internal bearings

• Heating jackets optional

• Grease or oil bath lubricated bearings

• PT 100 temperature monitoring

• Interchangeable with existing ISO 2858 pumps |

|

|

|

|

|

|

|

Self-priming centrifugal pumps

EN 733 (DIN 24255)

combiprime H

combiprime v

|

|

Features/Benefits

• Standardized and modular design

• Self-priming

• Built-in vacuum pump with external adjustment

• Large air displacement capacity, shortening suction times

• Flanges according to ISO 7005 PN 16

• Outstanding hydraulic performance

• High efficiency impeller

• Closed impeller with back vanes providing axial balancing

of impeller loads

• Mechanical seals to EN 12756 (DIN 24960)

• 2-Angular contact thrust bearings and cylindrical roller bearing

• Robust shaft design

• Extended life time

• Atex certification

• Easy maintenance through the Back-Pull-Out principle

• Sea water resistant version available

• Available in horizontal and vertical execution |

|

|

|

|

|

| |

The MDR-series in PP and PVDF |

|

|

|

|

Mag Drive seal-less centrifugal pumps are

virtually leak-proof since the design eliminates

the multitude of problems related to shaft seals

and packings.

Features/Benefits

• No leaking shafts Improved safety

• High corrosion resistance Wide range of applications

• Standard electric motors Simple and inexpensive replacement

• Reliable in performance Less down-time

• Simple design Easy maintenance

Suitable for

Sulphuric acid, caustic, sodium hydroxide, developer,

fixing bath, bleaching agent, various other chemicals

Technical data

Casing: PP filled with glass fibre, PVDF with carbon fibre

Impeller: PP filled with glass fibre, PVDF with carbon fibre

Max. capacity: 30 m3/h

Max. delivery head: 24 m

Max. liquid temp: 85?C for PP, 100?C for PVDF

Max. system pressure: 3 bar at 20? C

Max. speed: 2 800 rpm |

|

|

|

|

|

| |

Multistage Centrifugal Pumps |

|

|

|

|

The range of multistage pumps includes a series

of horizontal pump, MCH, and a range of vertical pump,

MCV. The horizontal types can also be supplied

in a self-priming version, MCHZ.

Features/Benefits

• Rigid, reliable construction

• High pump efficiency

• Low maintenance cost

• Mechanical seal or gland packing

• Atex Certification |

|

|

|

|

|

|

|

Robust centrifugal pump for liquids containing solids

|

|

Features/Benefits

• Can handle solids

• Vortex technology

• Prevent clogging

• Standardized and modular design

• Flanges according to ISO 7005 PN 16

• Available in horizontal and vertical execution

• Self-priming option available

• Atex certification

• Handle liquids with varying amounts of gas

• Impeller with back vanes providing solids kept away from

shaft sealing area

• Easy maintenance through the Back-Pull-Out principle

• Single unbalanced / balanced seals to EN 12756 (DIN 24960)

• Single and double cartridge seals with seal support system

• Quenched shaft sealing

• Gland packing

• Dry-shaft design, pumped liquid not in contact with the shaft

• Robust shaft design

• Extended life time

• Double row angular contact thrust bearing and cylindrical

roller bearing

• Grease or oil bath lubricated bearings

• In vertical execution many mounting options (floor, bulkhead)

• In vertical execution eight positions possible between suction

and delivery connections |

|

|

|

|

|

|

|

Vertical centrifugal pump to EN 733 (DIN 24255)

|

|

Features/Benefits

• Standardized and modular design

• Compact design

• Flanges according to ISO 7005 PN 16

• Many mounting options (floor, bulkhead, wall mounting)

• Eight positions possible between suction and

delivery connections

• Outstanding hydraulic performance

• High efficiency impeller

• Closed impeller with back vanes providing axial balancing

of impeller loads

• Spacer-coupling option for easy maintenance

• Easy maintenance through the Top-Pull-Out principle

• Mechanical seal to EN 12756 (DIN 24960)

• Atex certification

• Dry-shaft design, pumped liquid not in contact with the shaft

• Robust shaft design

• Extended life time

• 2-Angular contact bearing

• Bearing bracket option allows a wide range of shaft seals |

|

|

|

|

|

|

|

A sump pump designed to

EN 733 (DIN 24255), ISO 5199 - ISO 2858

/ EN 22858, API 610 / API 682

|

|

Features/Benefits

• Standardised and modular design

• Customized sump depths up to 10 m

• Outstanding hydraulic performance

• High efficiency impeller

• Closed impeller with back vanes providing axial balancing

of impeller loads

• Half open impeller with wear plate and external adjustment

• Oil seal standard shaft sealing. Gas tightening option

by mechanical seal or Gland Packing

• Discharge flange according to ISO 7005 PN16, PN20, PN50

or ANSI B16.5 150 lbs, 300 lbs

• Atex certification

• Pumped liquid lubricated silicon carbide radial bearings

• External lubrication optional

• Heavy duty grease lubricated double row angular contact

bearing for axial loads

• Standard IEC flange motor

• Mounting plate vapor tight or pressurized design

• Rectangular or circular mounting plate

• API 610 / API 682 execution engineered for hydrocarbon

and petrochemical processing industries |

|

|

|

|

|

|

|

Vertical sump pump to EN 733

|

|

Features/Benefits

• Compact standardized and modular design

• No shaft sealing

• Flanges according to ISO 7005 PN 16

• For stainless steel execution ISO 7005 PN20/150 lbs

ANSI B 16.5 available

• Outstanding hydraulic performance

• High efficiency impeller

• Closed impeller with back vanes providing axial balancing

of impeller loads

• Liquid lubricated slide bearing

• Standard IEC flange motor

• Atec certification |